Go Dutch

Tom Major™

Published: 12/2/2020

By: Bill Watters

In 2014 we packed up the kids and our belongings and moved from Ada, MI to Cincinnati, OH. My wife was the one moving up the career path that brought us down here, so I was Mr. Mom of 2 girls aged 4 and 6 and living in a small apartment until we could figure out where in the area we wanted to live. The kids kept me busy but being the hands-on maker type of person I am, and I was going crazy without my workshop.

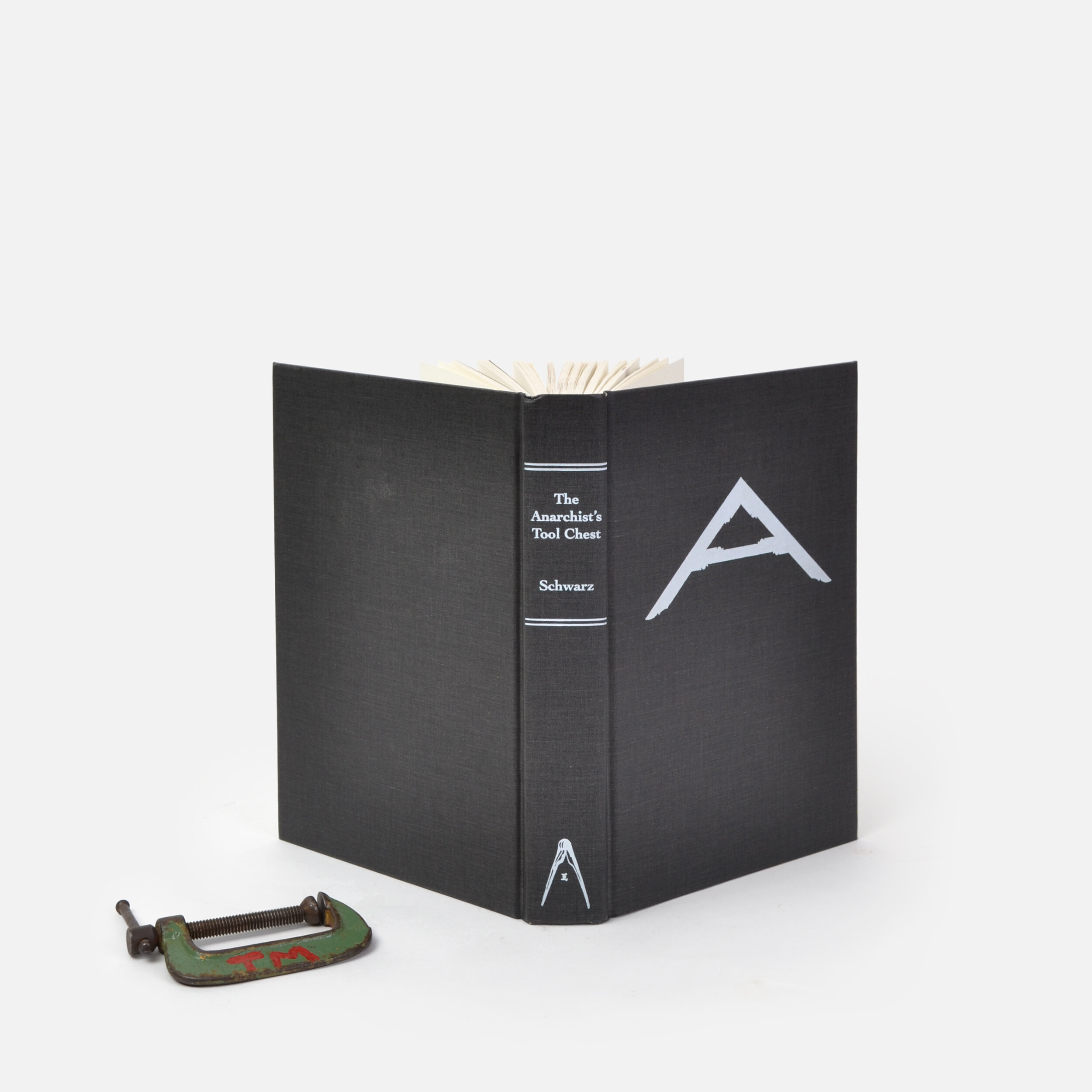

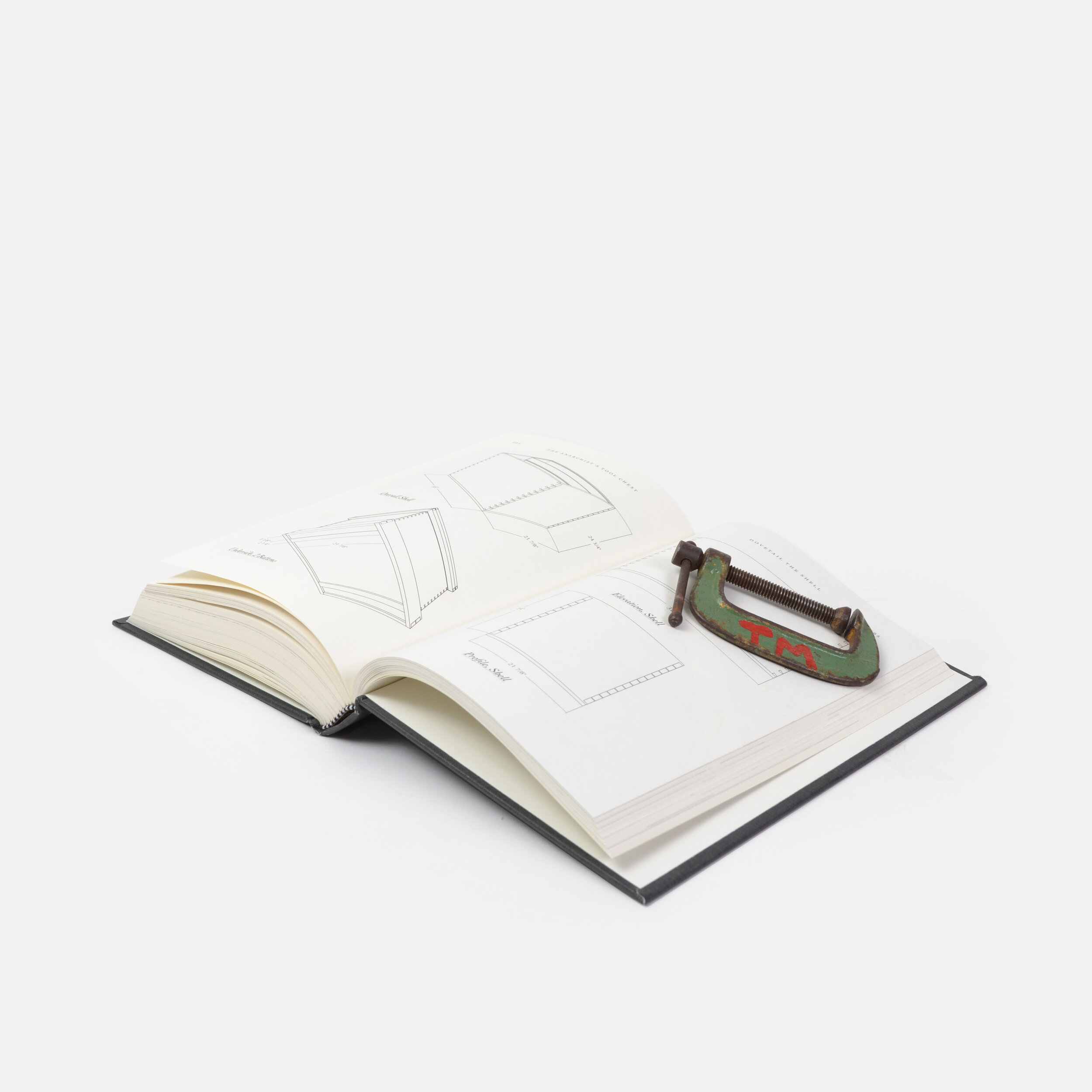

I decided if I can't use tools, I'd read a book about tools. The Anarchist Tool Chest by Christopher Schwarz, I never heard of him. I just thought I'd learn about some tools. Long story short, it changed my life. Maybe it was what I needed at the time, but I could relate on a number of different levels. From working with your hands to building things that would last, I realized that I don't need every power tool and store-bought jig to make something that will last for decades. Woodworking hand tools mostly have been the same for centuries, but some are best used in the trash can. It questioned where the quality went, why the skills disappeared, and the knowledge of woodworking, which used to be a part of life for centuries?

I thought it best to accumulate some of these necessary non-power tools to "pull the plug" on my woodworking because I was without a shop. I started looking on eBay and other used tool sites. I had a few of the key hand planes passed down from my grandpa Tom Major. You could find the 'TM' on every tool he owned, either painted or scribed somewhere on the tool. It fits my current position on the Stuff Staff because our Director, Andrew Neyer, also puts a ™ (trademark) on Everything™.

Fast forward to us buying a house, moving in, and having a space to work in the garage, and having several tools with nowhere to put them or protect them from the elements in the garage. I needed a tool chest. But I decided against the English floor chest that was detailed in the book. I was going Dutch. Why?

Smaller size, more portable

Cheap to make - 1x12 and 1x8 pine found at every big box home store.

Quick to make - the English chest has over 100 dovetails, build time 5-6 days (or a month in my case). vs. 2 days for the Dutch.

The Dutch tool chest came from the 18th century. In the Netherlands, the chest was used by shipwrights. Easily portable to move around the job site, and the slanted top protected the tools from the rain. The chest is dovetailed at the bottom to take the weight. The division between the top and bottom compartment is set in a dado on the sides and nailed outside. The boards that make up the back are tongue and grooved or shiplapped and also nailed in place. The use of nails helps with the wood movement and keeps the boards from splitting. The front and back have the grain running horizontally, while the grain on the sides run vertically, causing the wood to move in different directions. The chest is painted with milk paint. A quick, easily applied, and durable finish that protects the wood. Tool chests take a beating; it's quick and easy to apply more paint when needed. Heavy-duty handles make it easy to move around, and runners across the bottom keep it elevated off the floor.

It has worked out brilliantly in my shop. It can safely and securely hold all of my hand tools. It is easy to move around the shop. It is durable and easy to modify if need be. The slanted top keeps things from being piled on top and an excellent place for a cut sheet or drawings. Build one. It will probably outlive yourself and maybe your kids. Not bad for a few days of work and $60 in the material.

The Anarchist Tool Chest, By Christopher Schwarz

Thoughts

– Want to build one?

– Do we need Stuff toolboxes?

– Is Tom Major the real ™?